Whether automakers and vehicle OEMs will need advanced driver assistance (ADAS) applications to be successful in the future is not a question of "if" but "when." And high-performance custom SoCs will be critical to that success.

In my previous blog post, I talked about how the move toward electric and self-driving vehicles is accelerating and looked at how custom SoCs were becoming pivotal to the success of automakers looking to remain competitive in this shifting landscape.

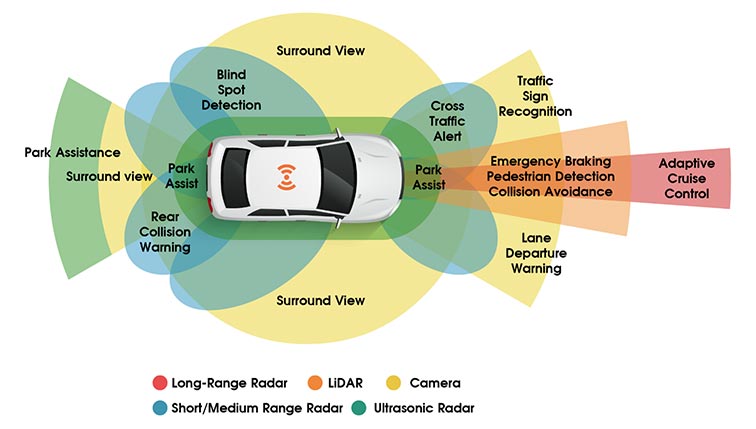

This time around, I would like to focus on ADAS and self-driving vehicle technology. Next-generation autonomous driving platforms require higher levels of performance to make split-second decisions. A vehicle must quickly comprehend, translate, and accurately perceive its surrounding environment to react safely to changes. Future ADAS and autonomous vehicle implementations demand higher performance, real-time edge computing with AI processing capabilities, and increased bandwidth interfaces to accommodate multiple high-resolution sensors, including radar, LiDAR, and cameras.

Improving the "seeing” or “vision" capabilities of advanced driver assistance systems extends beyond cameras and LiDARs, requiring the integration of smart sensors to handle complex driving scenarios that the auto industry coins Level 4, or "high" automation. Vehicle OEMs and automakers looking to meet these requirements have two fundamental choices when engineering their solutions: use a custom SoC or plug in an off-the-shelf chip. Read on for an analysis of each option.

Custom SoC Versus Off-the-Shelf Solutions

Let’s start with some simple definitions:

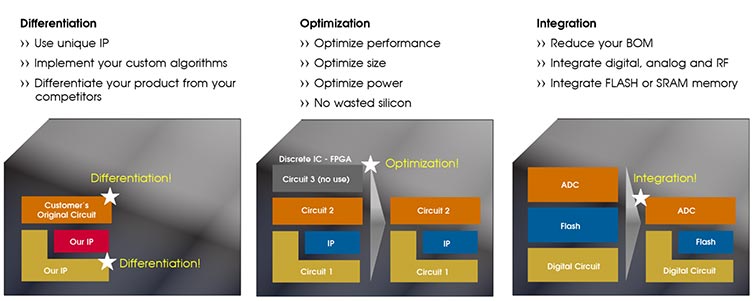

Custom system-on-chip (SoC) solutions use multi-purpose IP blocks specifically architected and integrated to provide the functions required by their target application and use case. A purpose-designed SoC can help OEMs achieve optimal performance and efficiency levels, reduce size requirements, and lower overall BOM costs.

Standard “off-the-shelf” (OTS) silicon solutions appeal to a broader-based market by meeting general-purpose requirements. As such, OTS silicon devices support functions that are not fully optimized or, in some cases, even utilized in the design, often resulting in a larger footprint, unnecessary power consumption, and performance inefficiency.

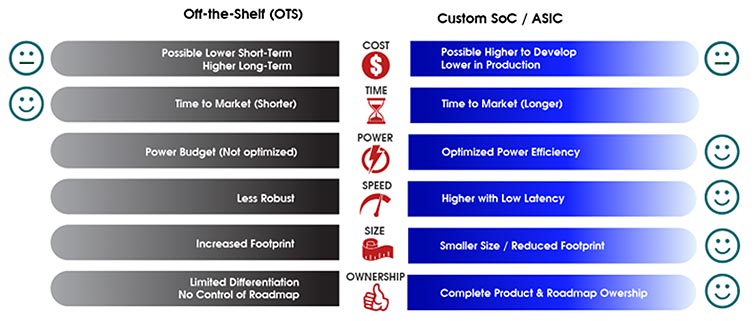

When auto OEMs decide whether to go with a custom SoC versus an off-the-shelf product in their design, there are many factors to consider. For example:

- Are they designing the vehicle for a broad-based market with little differentiation?

- Which critical IP should they bring in-house versus relying on generic solutions from external vendors?

- What tradeoffs are there regarding power, performance, size, and cost between custom and general-purpose chips?

Ultimately, automotive vendors must decide what is most suitable based on the available options. The diagram below lists some critical factors to consider when deciding between custom SoC and standard off-the-shelf products.

Why Custom SoC Solutions are the Optimal Choice when Designing Your Next Automotive Application

I highlighted several of the compelling benefits provided by SoC solutions above. But custom SoCs also offer particular advantages in two critical areas: competitive differentiation and supply chain security. Let’s briefly touch on each of these.

Custom SoCs and Competitive Differentiation

Custom SoC solutions provide OEMs and tier-one automakers the opportunity for complete ownership of key differentiating technologies in ADAS and autonomy. Proprietary chips allow companies to develop in-depth knowledge and in-house expertise, enabling greater control of future designs and product implementations.

Custom SoCs and Supply Chain Security

Supply chain interruptions are a primary concern for auto OEMs today. Unanticipated “black swan” events, such as natural disasters, international border blockades, government sanctions, economic downturns, and geo-political and social unrest, can disrupt the supply flow. Supply of materials is never guaranteed. However, the odds for continued production are more favorable when an OEM or automaker doesn’t have to compete with several other companies all vying for the same off-the-shelf components.

More and more car manufacturers are realizing that general-purpose chips offer features that cater to multiple customers, limiting their product competitiveness and restricting them to the suppliers' timelines and delivery schedules.

A Mini Case Study: Custom SoCs and a Successful Automotive Industry Disruptor

Now and again, a new company comes along and alters established business models. Netflix did it with the video rental industry. Telsa has done it in the automotive industry.

Tesla is a company that has shattered the traditional automotive business model with its early launch of autonomous driving technology, a direct purchasing program, unconventional automotive designs with large interior displays, and the construction of battery giga-factories. Unlike other automakers, Tesla was also early to recognize the importance of over-the-air (OTA) software updates for adding features to improve safety and performance. Tesla’s success is driving traditional automakers to adapt their playbooks rapidly.

Tesla joined other tech giants like Google, Amazon, Cruise, and many others that have decided to develop their own proprietary autonomous driving platforms. To further that effort, the company started developing proprietary chips in 2016, and custom SoCs have been a fundamental ingredient in Tesla’s success:

- Tesla was also one of the earliest companies to implement autonomous driving technologies with its 1st generation autopilot launch in 2016.

- In 2019 at Autonomy Day, Tesla unveiled Hardware 3.0. Elon Musk claimed it was “objectively the best chip in the world.”

- Earlier in 2022, rumors circulated that Tesla was working with Samsung to develop a new 5nm semiconductor chip that would assist with its autonomous driving software.

To build a self-driving car, automakers must combine hardware, software, and data to train the deep neural networks that allow a vehicle to perceive and move safely through its environment. Deep neural networks, with their algorithms specifically designed to mimic the working of neurons in the human brain, are the artificial intelligence engine that will enable autonomous vehicles. They are the backbone of deep learning. The evolution of Tesla's autopilot and full self-driving features forced carmakers to take a closer look at the use of cameras and ultrasonic sensors.

Tesla acquires a tremendous amount of data from its nearly two million autopilot-enabled vehicles, each equipped with eight camera arrays to generate data to train the neural networks to detect objects, segment images, and measure depth in real time. The car’s onboard supercomputer FSD (full self-driving) chip runs the deep neural networks, analyzing the camera's computer vision inputs in real-time to understand, make decisions, and move the car through the environment.

As AI becomes more critical and costly to deploy, other companies, such as Google and Amazon, are also designing custom chips.

In addition to being a crucial component of full self-driving capabilities, autonomous vehicle OEMs aim to develop proprietary chips to differentiate themselves from their competition.

Choosing the Right Partner

Creating a proprietary chip requires a complex, highly structured framework with a complete support system for addressing each phase of the development process. Most companies seeking to design custom chips do not have the full capabilities in-house. They require assistance from highly specialized companies with extensive engineering skills, know-how, and experience to support end-to-end system-level SoC design, development, and implementation.

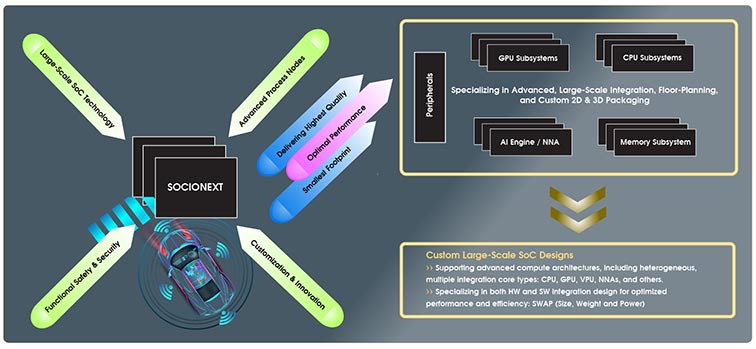

A company such as Socionext offers the right combination of IPs, design expertise, and support to implement large-scale, fully customizable automotive SoC solutions to meet the most demanding and rigorous automotive application performance requirements.

Socionext has an in-house automotive design team to help to facilitate the early development and large-scale production of high-performance SoCs for automotive applications. As a leading “Solution SoC” provider, Socionext is committed to using leading-edge technologies, such as 5nm and 7nm processes, to produce automotive-grade SoCs that ensure functional safety while accelerating software development and system verification.

Contact us today to learn more about how Socionext can assist with your next custom SoC development.